Why Revisit?

We initially broached the topic of “cutdowns” in Post #4; in this issue we’ll delve into the cutdown a bit more and speculate how it probably transitioned to homebuilt–bodied speedsters.

It’s All in the Name

Words have origins, and many word origins emerge from slang, words appropriated that were used for other purposes. Many times from other languages. We’ve defined the term “Speedster” in previous posts; let’s review:

A Speedster is a simple but powerful car meant for fun and adventure.

Many manufacturers have used the term, and some have even tried to trademark it for their exclusive use. Unh-uh, can’t do.

Why? Because the term “speedster” is vernacular, a word that rose up from the people. It’s a slang term used to describe something that went fast: a person, a bicycle, a boat, a car. Whatever…

Cutdowns and Gow Jobs

A popular early speedster was made from stripping the body off of a cheap donor, such as a used Model T or, later on, a Chevrolet 490. This was a groundswell moment in the car hobby, as thousands of backyard enthusiasts created their own racy-looking speedster, whether from a manufactured kit or by their own ingenuity.

Cutdown speedsters were indeed a phenomenon of the early 20th century, as seen by these images culled from family photo albums and library collections.

These were called “cutdowns.” To define the term:

A cutdown speedster is a bare-bones road car, comprised solely of a frame, seats, drive train, and engine cowling.

1915 Tapco Body kit illustration courtesy AACA Library

The cutdown also had oil and gas tanks strapped to the deck behind the seats. Spare tires were an option and often mounted off the rear bumper. Lights were mounted for after-dark work. Brakes too, but they were often fitted to the rear wheels only. After all, who needs brakes? Speedsters were meant to go!

Early cutdown from Brunswick, GA. Note the chisel-point radiator, a popular option found in early speed accessory catalogs. Is this guy getting a ticket, or what?

There is no exact number on how many Model Ts were stripped of their bodies to make a cutdown. Keep in mind that these speedsters were imitating what was also being manufactured by companies at that time who had got wind of the homebuilt movement. Companies such as Tapco, Auto Sheet Metal Works, or Remo would offer the basics, from which one could build more of a car if one wanted more than just the cutdown body. Or not.

1915 Auto Sheet Metal speedster body. Illustration courtesy ACA Library

Remo Raceabout body kit, another option.

Manufacturers such as E.M.F. made and sold Flanders roadsters and speedsters in this configuration. They were simple, racy-looking, and they attracted attention.

1912 Flanders Model 20 Speedster. Catalog image You can read more about Flanders in my two-part series beginning in Post 6.

However, that didn’t mean that the owner wouldn’t take that manufactured speedster and hop it up some more! More on “hop up” in a moment…

1912 Flanders “Blitzen Bean” in 1913. Definitely modified from the “street” version, this speedster is the subject of Post 5, Cutdown Champion.

Cutdowns often emulated their track-based cousins, some of which were powerful racers such as the Stutz Bearcat or the Mercer Raceabout. Model T-based racers were raced at county fairs and hillclimbs, sometimes sanctioned, sometimes “outlaw” events. The race cars were often described as “gow jobs” and being “souped up,” terms whose origins are discussed in a couple of posts in the Jalopy Journal, published by the H.A.M.B. forum.

Model T track racer. The young lad at left may only be the shop sweeper, but he is no doubt dreaming of racing one day too!

Digressing for a moment to delve into period slang, a poster in the Jalopy Journal from November 2007 stated that in the early 1900s “gow” was slang for opium (literally: “sap,” which it is) and “soup” was slang to describe cocaine. Terms like “juiced” or “hopped up” were also period terms from the drug world that were used to describe the effects after ingesting a controlled substance, words that linger today to describe something that has been altered in a suspicious and perhaps illegal way.

Naturally, these slang terms made their way into the speedster movement to characterize how “hot” speedsters were, especially after putting some forbidden nitroglycerine in their tanks when no one was looking. The early 20th century was a time when exciting things to see or do were “hot,” like a hot dog, a hot idea, a hot date, a hot rod. At some point the lattermost became one word.

And if one threw in a frowned-upon slang word or two, comments among early speedsterites no doubt ensued like

“Man! Your gow job sure is hot! It’s gotta be juiced!”

Nothing adds pizzazz quite like slang, and the classic speedster era had it in spades!

Home-Built Bodies

Cutdowns were a lot of fun for the young and adventurous, but enough spills on a rutted dirt road probably made speedster pioneers think twice about careening around in an open cockpit: no safety, no restraining belts, no roll bar. Hence the need for something less prone to injury. Enter the homebuilt sports body.

For young builders of limited means, even purchasing a coachbuilt body from a catalog, speed shop, or a body manufacturer was a challenge. Prices in the nineteen-teens ranged from $50 to $150 for something that would cover the chassis and enclose the passengers, an expensive proposition for the youth of this period. The ready-made open platforms, such as Tapco and others, were less expensive at $35-$100, but still, out of reach for many. Hence, the third option emerged; the “By gum, let’s do it ourselves!” route!

Concurrent with trends in Model T Fordism as seen in the experimentation by backyard tinkerers – stripping off T bodies, fitting aftermarket bodies, or even making one’s own homebuilt body - newspaper and magazine folks soon started to chronicle this emerging phenomenon.

Beginning in 1915, Murray Fahnestock, technical editor of a monthly publication called The Fordowner, took it upon himself to publish articles about what was being done to Model Ts, specifically street speedsters and track racers. His invaluable work gives modern readers an insight regarding what was being done at that time to make the Ford fast and fun.

One aspect that he covered was the transition from cutdown to sport-bodied speedsters, including ideas for those at home who would rather make their own bodies.

Early homebuilt speedster body, as seen in The Fordowner. Fordowner images courtesy AACA Library

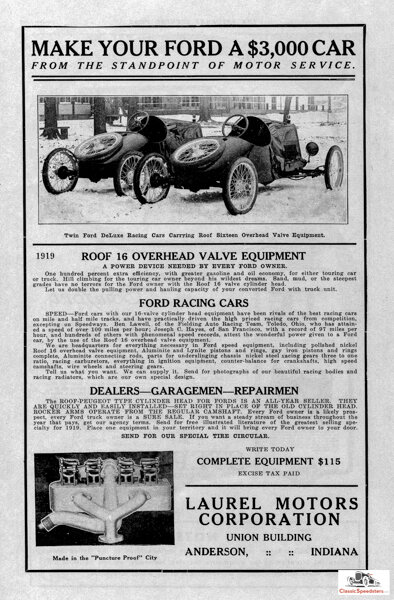

Extensive coverage of how to shorten the frame, lower it, and reinforce it for better performance and safety were covered by Fahnestock as well as guest writers in the industry such as Robert Roof, chief engineer of Laurel Motors Corporation, and Louis Chevrolet, race driver, designer, and partner with his brother Arthur in the Frontenac Corporation.

1919 Laurel Motors ad. Illustration courtesy AACA Library.

1926 Frontenac Corporation. Note the images of Arthur and Louis Chevrolet, plus Henry Ford sitting in their Indy racer. catalog image courtesy Larry Sigworth collection

Articles by Fahnestock and other contributors over several years covered several topics, such as engine and transmission modifications to beef up drivetrains, fitting fenders and wheel coverings for safety, current refinements in body design as seen by comparing various body manufacturers, and detailing how to create a top to guard against bad weather.

However, in his August 1923 article, Fahnestock went right to the heart of the matter that addressed how one could make a low-cost body for his or her speedster. As Fahnestock stated:

Many Ford speedster bodies are thrown together by impatient builders who are anxious to try-her-out on the road, resulting in the haphazard eyesores so frequently seen on the road. But better and more beautiful bodies have been made – and perhaps even more easily – if a little planning and foresight had been used in the design.

Fahnestock’s article featured the Red-I-Kut system, produced and sold by the Kuempel Co. of Dubuque, Iowa.

Kuempel build-it yourself speedster body kit. Illustration courtesy Horseless Carriage Foundation Library

For only $6.00, a princely sum in 1920 for a young soul just starting out, and using this product that consisted of a set of numbered patterns, one would cut out the patterns as instructed. Then, as Fahnestock wrote:

Paste the sheets together using flour or library paste, taking care that no buckles occur, and that the lines which continue from one sheet to another make a perfect continuation.

And:

Make a thorough study of the patterns, the shape of the parts they represent and the position these parts occupy in the completed body.

The photo shows the young hobbyist fitting pattern pieces to the body as directed. (Foto 11 fitting pieces)

The Red-I Kut system in action, as seen in The Fordowner article. Note that the young assembler is wearing a striped shirt and a tie, topping off with a newsboy cap as well.

Red-I-Kut body, oblique angle cutaway, from The Fordowner article.

Fahnestock provided detailed information which may have been word-for-word directions from the pattern kit. One can see from the oblique-angled cutaway drawing that a well-framed taper-tail speedster would be duly constructed; the illustration in the ad above confirms that it would be the smart-looking Model K9.

Fahnestock’s work has been reproduced in three books that are still available:

Model T Speed Secrets: The Fast Ford Handbook

Model T Ford in Speed and Sport

The Model T Fordowner

These are published by Lincoln Publishing and found though many online booksellers.

The Fun Continues…

Cutdowns and homebuilts are still being made and enjoyed by hundreds (maybe even thousands!) of vintage Ford and Chevrolet enthusiasts who are passionate about their cars. One reader of this journal recently shared a link to his video of a 2018 hillclimb event from Newport, Indiana, in which almost 20 vintage speedsters participated.

You can see his video on YouTube at this (copy & paste) link:

https://youtu.be/VaL2zLC3qT8

A very nice example of a contemporary homebuilt Model T cutdown was made by Larry Schuknecht of Clarence Center, New York. Beautifully clad in copper and appropriately named “Penny.” Of course!

Penny Model T Speedster. Image courtesy Larry Schulnecht collection

A very active vintage speedster group called the Northwest Vintage Speedsters was previously mentioned in Post #4. It operates out of Portland, Oregon and has many member cars: cutdowns, homebuilts, and what appears to be a few manufactured bodies appear in their photo collection. Go check it out at www.nwvs.org.

We’d like to share stories that you may have of a speedster in your life, present or past, so if you have something that you think might be of interest to others, please send in a photo, a story, or a means to contact. It may be that we can include it with other cars of a similar theme for a future post. For instance, I am currently gathering stories of overseas speedsters to present at a later date.

See you around the bend!